NASA, Northrop Grumman to Send Medical, Technology Studies to Space

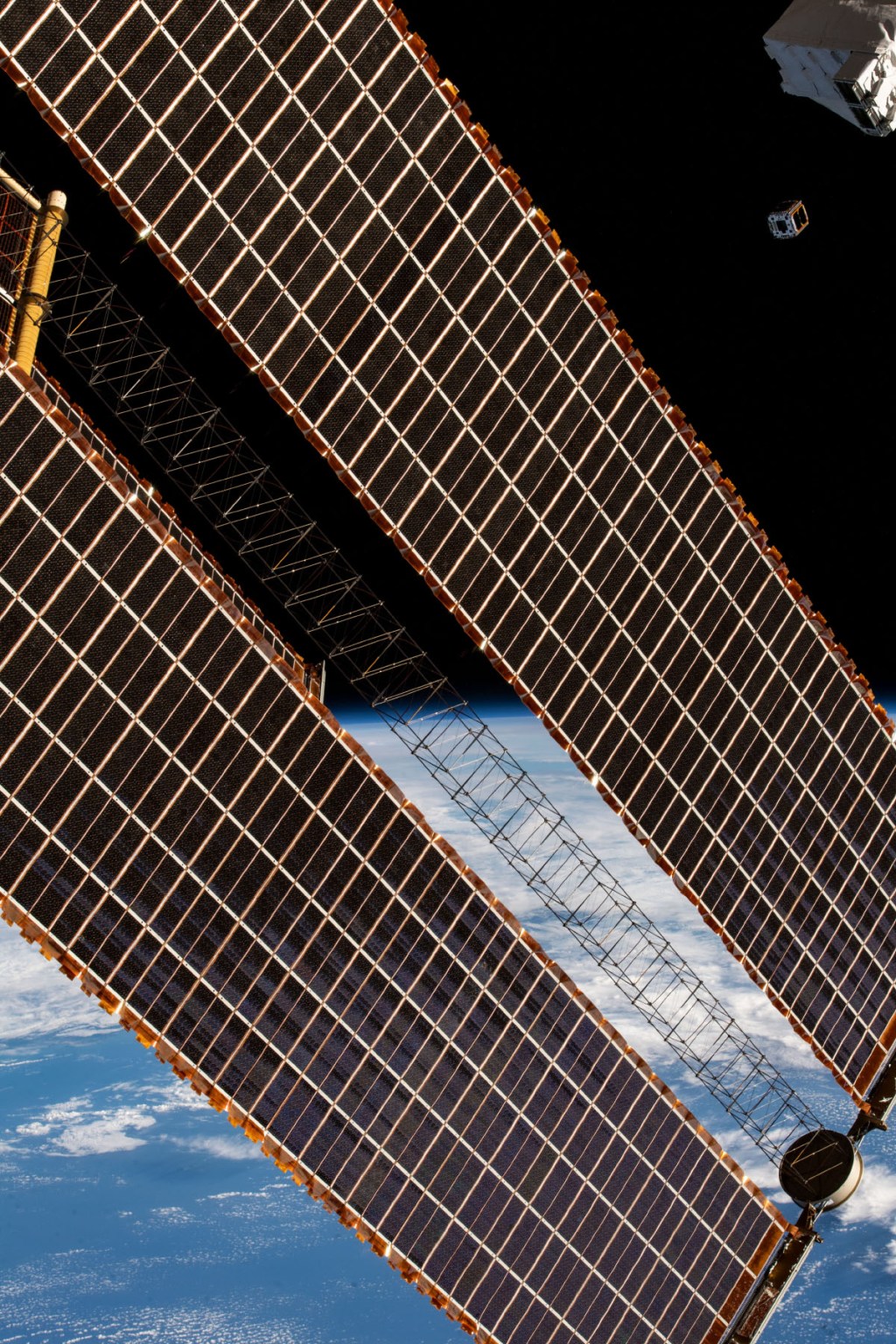

NASA and Northrop Grumman are preparing to send the company’s next cargo mission to the International Space Station, flying research to support Artemis missions to the Moon and human exploration of Mars and beyond, while improving life on Earth. SpaceX’s Falcon 9 rocket will launch Northrop Grumman’s 23rd commercial resupply services mission to the orbiting laboratory.

The investigations aboard the Cygnus spacecraft aim to refine semiconductor crystals for next-generation technologies, reduce harmful microbes, improve medication production, and manage fuel pressure.

NASA, Northrop Grumman, and SpaceX are targeting launch in mid-September from Space Launch Complex 40 at Cape Canaveral Space Force Station in Florida.

Read about some of the investigations traveling to the space station:

Better semiconductor crystals

Researchers are continuing to fine-tune in-space production of semiconductor crystals, which are critical for modern devices like cellphones and computers.

The space station’s microgravity environment could enable large-scale manufacturing of complex materials, and leveraging the orbiting platform for crystal production is expected to lead to next-generation semiconductor technologies with higher performance, chip yield, and reliability.

“Semiconductor devices fabricated using crystals from a previous mission demonstrated performance gain by a factor of two and device yield enhanced by a factor of 10 compared to Earth-based counterparts,” said Partha S. Dutta, principal investigator, United Semiconductors LLC in Los Alamitos, California.

Dutta highlighted that three independent parties validated microgravity’s benefits for growing semiconductor crystals and that the commercial value of microgravity-enhanced crystals could be worth more than $1 million per kilogram (2.2 pounds).

Space-manufactured crystals could help meet the need for radiation-hardened, low-power, high-speed electronics and sensors for space systems. They also could provide reduced power use, increased speed, and improved safety. The technology also has ground applications, including electric vehicles, waste heat recovery, and medical tools.

Learn more about the SUBSA-InSPA-SSCug experiment.

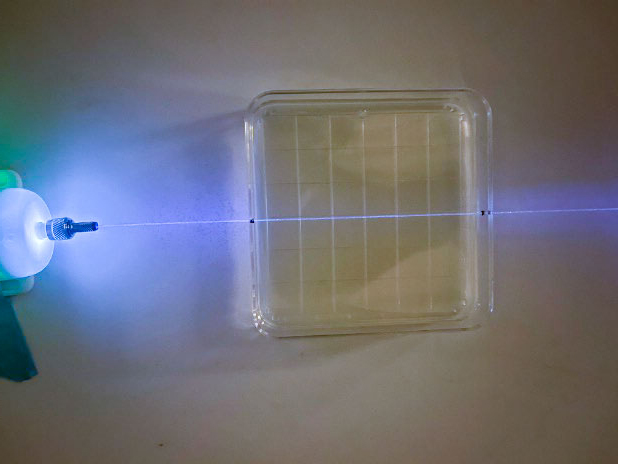

Lethal light

Researchers are examining how microgravity affects ultraviolet (UV) light’s ability to prevent the formation of biofilms — communities of microbes that form in water systems. Investigators developed special optical fibers to deliver the UV light, which could provide targeted, long-lasting, and chemical-free disinfection in space and on Earth.

“In any water-based system, bacterial biofilms can form on surfaces like pipes, valves, and sensors,” said co-investigator Paul Westerhoff, a professor at Arizona State University in Tempe. “This can cause serious problems like corrosion and equipment failure, and affect human health.”

The UV light breaks up DNA in microorganisms, preventing them from reproducing and forming biofilms. Preliminary evidence suggests biofilms behave differently in microgravity, which may affect how the UV light reaches and damages bacterial DNA.

“What we’ll learn about biofilms and UV light in microgravity could help us design safer water and air systems not just for space exploration, but for hospitals, homes, and industries back on Earth,” Westerhoff said.

Learn more about the GULBI experiment.

Sowing seeds for pharmaceuticals

An investigation using a specialized pharmaceutical laboratory aboard the space station examines how microgravity may alter and enhance crystal structures of drug molecules. Crystal structure can affect the production, storage, effectiveness, and administration of medications.

“We are exploring drugs with applications in cardiovascular, immunologic, and neurodegenerative disease as well as cancer,” said principal investigator Ken Savin of Redwire Space Technologies in Greenville, Indiana. “We expect microgravity to yield larger, more uniform crystals.”

Once the samples return to Earth, researchers at Purdue University in West Lafayette, Indiana, will examine the crystal structures.

The investigators hope to use the space-made crystals as seeds to produce significant numbers of crystals on Earth.

“We have demonstrated this technique with a few examples, but need to see if it works in many examples,” Savin said. “It’s like being on a treasure hunt with every experiment.”

This research also helps enhance and expand commercial use of the space station for next-generation biotechnology research and in-space production of medications.

Learn more about the ADSEP PIL-11 experiment.

Keeping fuel cool

Many spacecraft use cryogenic or extremely cold fluids as fuel for propulsion systems. These fluids are kept at hundreds of degrees below zero to remain in a liquid state, making them difficult to use in space where ambient temperatures can vary significantly. If these fluids get too warm, they turn into gas and boiloff, or slowly evaporate and escape the tank, affecting fuel efficiency and mission planning.

A current practice to prevent this uses onboard fuel to cool systems before transferring fuel, but this practice is wasteful and not feasible for Artemis missions to the Moon and future exploration of Mars and beyond. A potential alternative is using special gases that do not turn into liquids at cold temperatures to act as a barrier in the tank and control the movement of the fuel.

Researchers are testing this method to control fuel tank pressure in microgravity. It could save an estimated 42% of propellant mass per year, according to Mohammad Kassemi, a researcher at NASA’s National Center for Space Exploration Research and Case Western Reserve University in Cleveland.

The test could provide insights that help improve the design of lightweight, efficient, long-term in-space cryogenic storage systems for future deep space exploration missions.

Learn more about the ZBOT-NC experiment.

Download high-resolution photos and videos of the research highlighted in this feature.

Learn more about the research aboard the International Space Station at:

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0